REHAB-LAB "3D printing and assistive devices, from patient to maker"

Name of Practice: REHAB-LAB "3D printing and assistive devices, from patient to maker"

Organisation: Kerpape Rehabilitation Center

Country: Ploemeur, France

Description of the Organisation: The Kerpape Rehabilitation Center is one of the biggest rehabilitation centers in France, relying on more than 50 years of experience in care for patients with motor disabilities and/or brain-damage. Kerpape Rehabilitation Center develops multi-disciplinary care to address these issues, based on multiple skills (neuropsychologists, speech therapists, occupational therapists, doctors, engineers, physiotherapists, etc.). In collaboration with both academic and industrial partners, many research projects have been developed in the field of assistive technologies: clinical and biomedical research (multi-centric studies), augmentative and alternative communication, robotics, home automation, driving rehabilitation.

Year of Initiation: 2016

Funding: The practice is funded by the French CNSA and Digital Health Europe programmes. It is also self-funded through trainings given to various healthcare professionals

Link to UNCRPD: Article 19 – Living independently and being included in the community

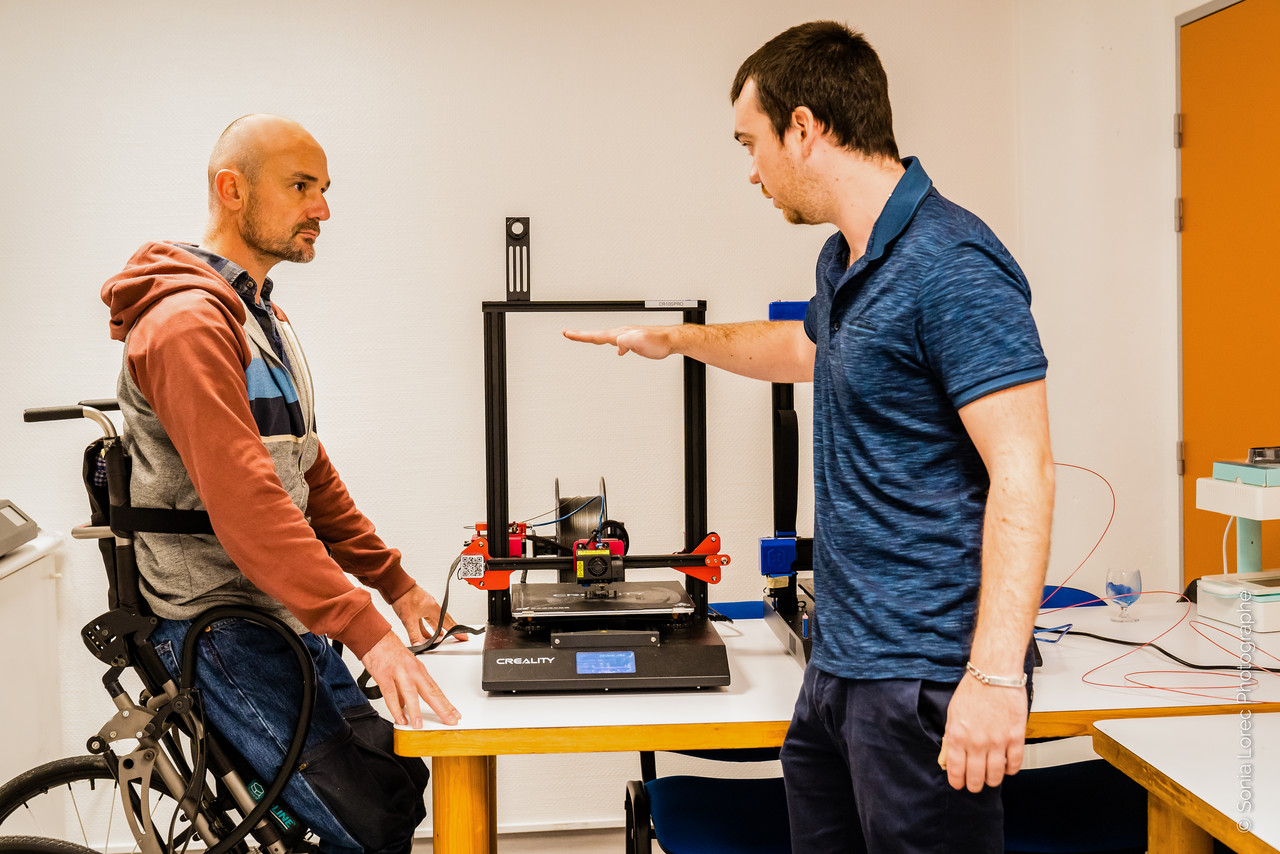

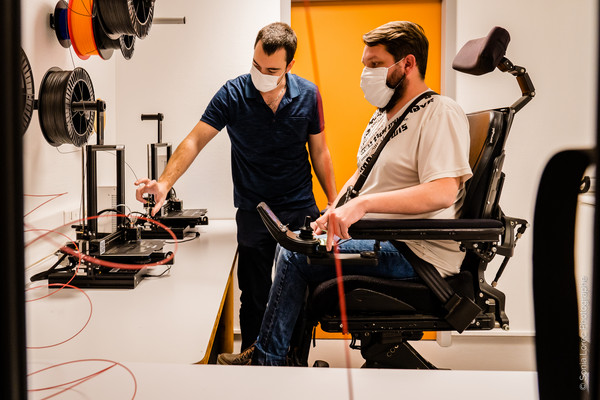

Description of your practice: REHAB-LAB is a fully integrated fabrication laboratory within rehabilitation or medico-social organisations, where citizens/patients with a disability become ‘designers’ to create their own assistive devices using 3D printing. The REHAB-LAB initiative began in France in 2016 with Kerpape, which is now one of the biggest rehabilitation centres in France. Through the support of the Digital Health Europe programme, REHAB-LAB is now expanding into different countries and has been promoted by the European Commission as an example of scaling up innovation. The new 3D tool promotes an innovative digital fabrication process within healthcare organisations, especially in occupational therapy, further empowering patients to be part of the solution by making their own assistive devices.

Problem Targeted: Several European studies highlight a high abandonment rate of assistive devices one year after starting use. 3D printing is a promising solution for health and care systems to tackle this issue, helping to design custom-made assistive devices, and involving users in designing their own assistive devices to improve acceptance and usage rates.

Solution Offered: Compared to non-digital fabrication processes, REHAB-LAB's 3D printing method comes with several benefits.

- Accessibility: Providing patients with the possibility to design their own assistive devices simply by having access to a computer.

- Adaptation: Ease of design by simply changing parameters on an existing object

- Cloning: Ease of reproduction in reprinting the object.

- Design: Possibility for patient to choose a desirable and convenient colour and shape.

- Cost and time efficient: The materials used and the 3D printing process itself harbour cost and time benefits.

Impact generated by the practice: As of September 2021, the emerging REHAB-LAB community is composed of 31 health and care organisations, who have involved more than 700 users in the process and designed over 1000 assistive devices.

In empowering patients to be involved in designing their assistive devices, they are encouraged to take charge of their own rehabilitation process. This dynamic further promotes an interaction between the patient and the healthcare professional. Whilst patients can focus on the design process and personalisation of the device, the healthcare professional can focus on the technology and specification behind the product. Moreover, with a new collaborative IT platform, individuals will be able to share 3D printable assistive devices, best practices, and field experts easily with one another. This will boost knowledge-sharing and further promote innovation within the sector.

Sustainability of the practice:

The Covid-19 situation in Europe has recently showcased the endless possibilities that come with fabrication laboratories, helping to design and manufacture personal protective equipment. With global supply chains suddenly being cut off, the issue of local manufacturing has become crucial and a pressing matter. REHAB-LAB has been concretely developing a model of distributed production that is both local and ‘custom-made’ - all thanks to its 3D printers. This production is adaptable and capable of producing prototypes and quickly replicating them in a distributed fashion through online networks and ecosystems. It is this model that is being tested on a large scale today, while the makers are mobilizing to try to produce on the network, much more and faster.

Contact information: Willy Allegre, Head of Innovation: willy.allegre@mutualite29-56.fr

Additional links:

- REHAB LAB PLATFORM - https://rehab-lab.org/

- Découvrez REHAB-LAB - la communauté des FABLABS intégrés, spécialisés et solidaires - YouTube

- REHAB LAB . CMRRF de Kerpape. FRANCE - YouTube

- Scaling up innovations via the DigitalHealthEurope twinnings: self-designed 3D printed assistive devices designed in Europe | Shaping Europe’s digital future (europa.eu)